| Items | Specification | |

| Production capacity | 1200Buckets/hour | |

| Bottle’s capacity | 18. 9 Liters (equal to 5 gallons) | |

| 11. 3 Liters (equal to 3 gallons) | ||

| Bottle’s specification (mm) | Φ270×490×Φ56 | |

| Φ230×420×Φ56 | ||

| Cap’s specification (mm) | Φ58×40 (strip:L18mm,W:7.5mm) | |

| Rated input power | 15.80KW | |

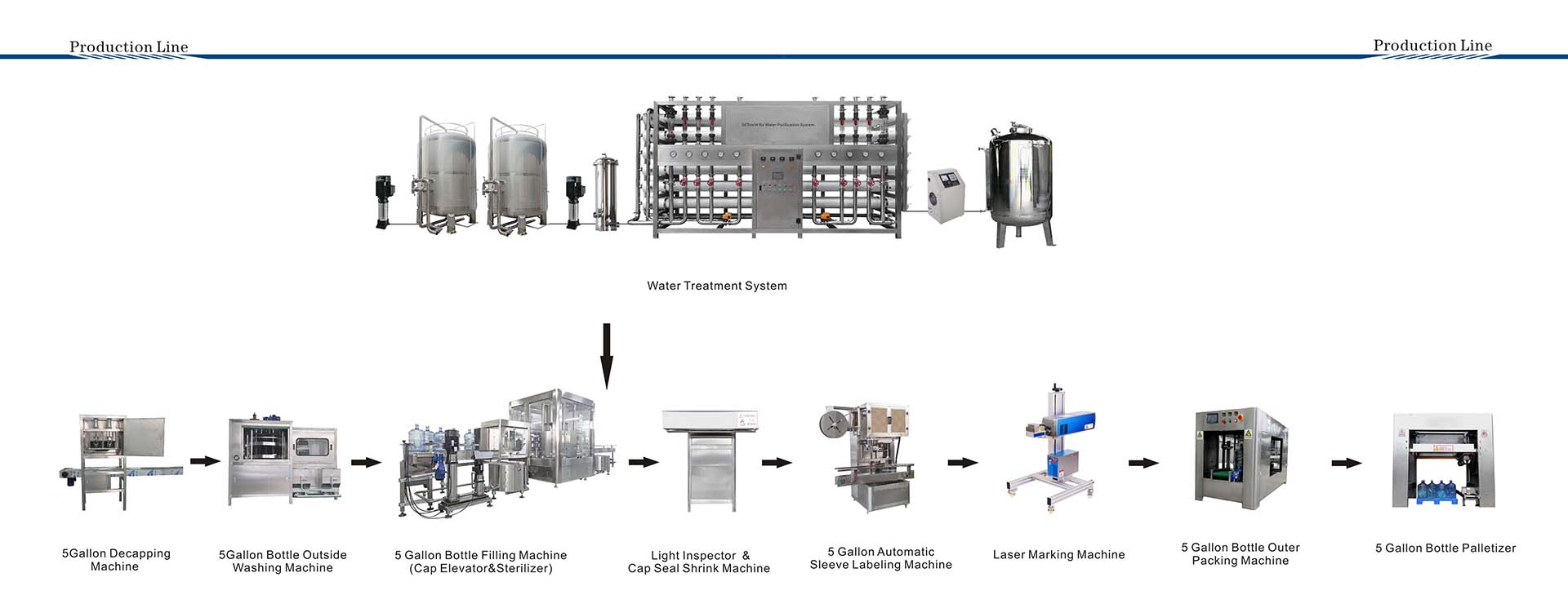

Product Details

Water filling plant production line

Features:

1) Controlled by PLC with the functions of automatic finish, precise orientation, little manpower and low working intensity.

2)The complete set of equipment is manufactured by high-strength stainless steel materials and stainless plate steel with precise argon arc, little distortion and fair welding veins

3) Beautiful appearance, anti-corrodibility, thorough disinfection, effective anti-air pollution and high quality

4) Microcomputer Auto Bottle Washer & Filler and Capper in one unit.

5) Body material: SS304.

1200BPH 5 Gallon filling machine

| Electromotor power | Bottle convey motor for washing process | 0.75KW*1 |

| Bottle convey motor for filling | 0.55kw * 1 | |

| Bottle Washing Pumps | 0.75kw *8 | |

| filling pump | 0.55KW*6 | |

| Cap-aligning electromotor | 0.06 KW | |

| Power supply | AC 380V±5% 50Hz | |

| Rated current | 28A | |

| Overall Dimension | Bottle Washing Part: 6126×2060×2050 mm | |

| Bottle Filling Part: 3265×800×2050 mm | ||

| Working Position | Six rows Fourteen stations for bottle washing, Six filling nozzles and six capping heads | |

| First, second washing positions: Hot caustic soda water washing | ||

| Third washing position: clean water(tap water) washing | ||

| Fourth position: drip out | ||

| Fifth, sixth, seventh, eighth and ninth position: disinfectant water washing | ||

| Tenth position: Drip out | ||

| Eleventh and twelfth washing position: Clean water(tap water) washing | ||

| Thirteenth position: drip out | ||

| Fourteenth washing position: pure water washing | ||

| Main Components | 1)Signal Relay(OMRON); | |

| 2)PLC(LS) | ||

| 3)AC contactor(LS/Schneider) | ||

| 4)Gearing motor | ||

| 5)Proximity switch(TURCK) | ||

| 6)Creepage air switch (Schneider) | ||

Feed machine

Filliing nozzle

Water bottle filling plant

Water bottle filling plant

Leonard Industrial specializes in designing, engineering, manufacturing and delivery of different types of water treatment systems and bottle water & beverage filling packing machineries for the food, beverage, dairy, chemical, and environmental protection industries. We are aiming to develop long-team relationships with our customers and suppliers, working closely on project development and achieve complete customer satisfaction by providing excellent quality & reliable machineries, zero defect delivery, first class services and competitive prices.