Machine Dimension |

3950*750*1960(L*W*H.mm) |

Max packed size |

600*400*350(L*W*H.mm) |

Shrinkage film material |

PE、PP、PVC、POF |

Shrinkage film thickness |

0.03-0.15(mm) |

Oven temperature |

160 - 250°C |

Heat Cutting Tempreature |

160 - 200°C |

Max output |

3-6Bag/Min. |

Actual Power |

15Kw/H. |

Max power consumption |

18KW |

Voltage |

AC 380V/220V,3Phs |

Weight |

750kg. |

Applicable Internal Diameter of Paper Tube |

5″~10″. |

Product Details

Auto shrink- wrapping machine series are suitable for the package of bottled water ,beverage、household、 electric appliances、electrical units、floor boards、pottery and so on.

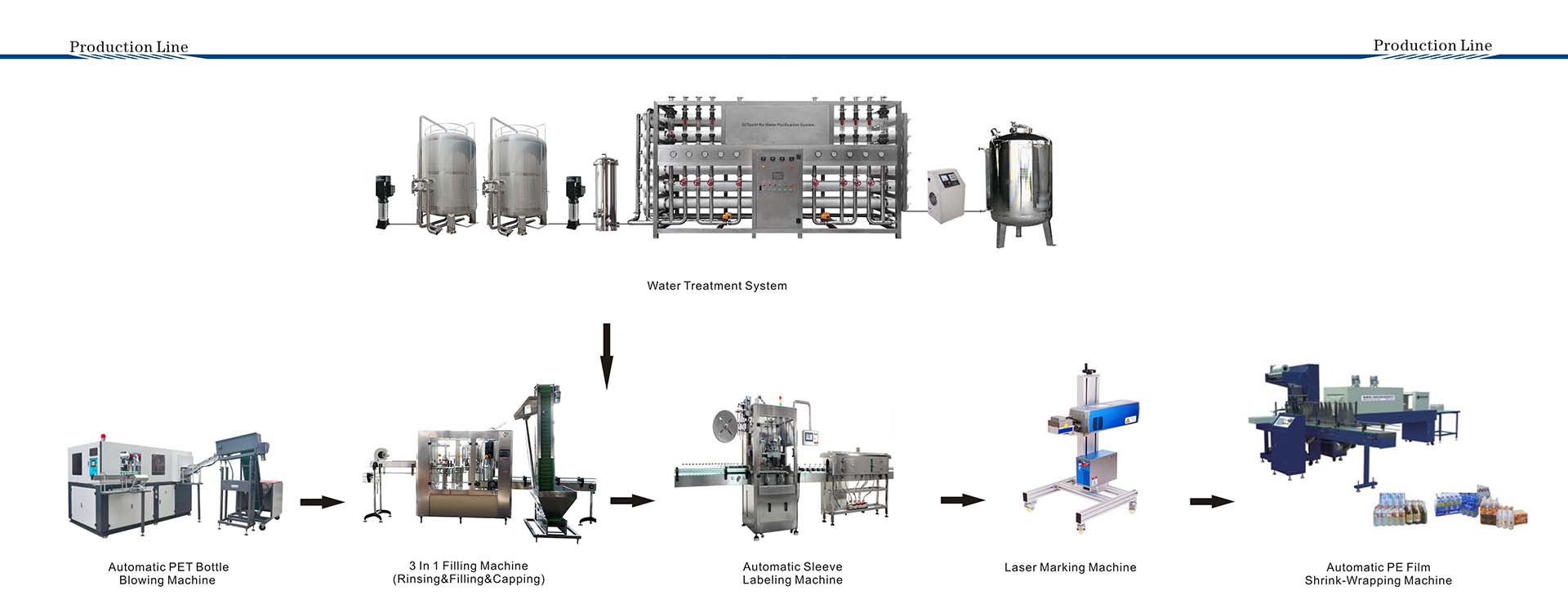

Bottled Drinking Water Plant

1) It can make package perfect whatever it is without pallet, cartoon, rectangle, round or flat shape.

2) It has the advantage of less cost and better appearance.

3) Replace film conveniently. It has failure alarm, lock device, reliable running.

4) Automatic film feeding and cutting function, and the length of film for feeding and cutting is adjustable.

5) With stainless steel heating tube to ensure the high efficiency even heat, not easy to break and easy changing.

6) The whole machine applies super steel and stainless steel, with compact and endurable structure. This new type of wrapping machine is the ideal equipment for beverage filling line.

Semi Auto Shrink- Wrapping Machine

Features:

- Shrink the film around the cap, extending the storing time.

- When bottle come pass the steam tunnel and detected by photoelectric sensor the steam solenoid valve will open and the high pressure & temperature steam will erupt from the steam generator and process the heating and shrink for the label on the bottle neck.

Semi Auto Shrink- Wrapping Machine

Semi Auto Shrink- Wrapping Machine