Production capacity: |

150 Bottles/hour |

||

Bottle’s capacity: |

1)18.9 Liters (equal to 5 gallons); |

||

Cap’s specification (mm) |

Φ58×40 (strip:L18mm,W:7.5mm) |

||

Rated input power |

2.3KW |

||

Working Positions |

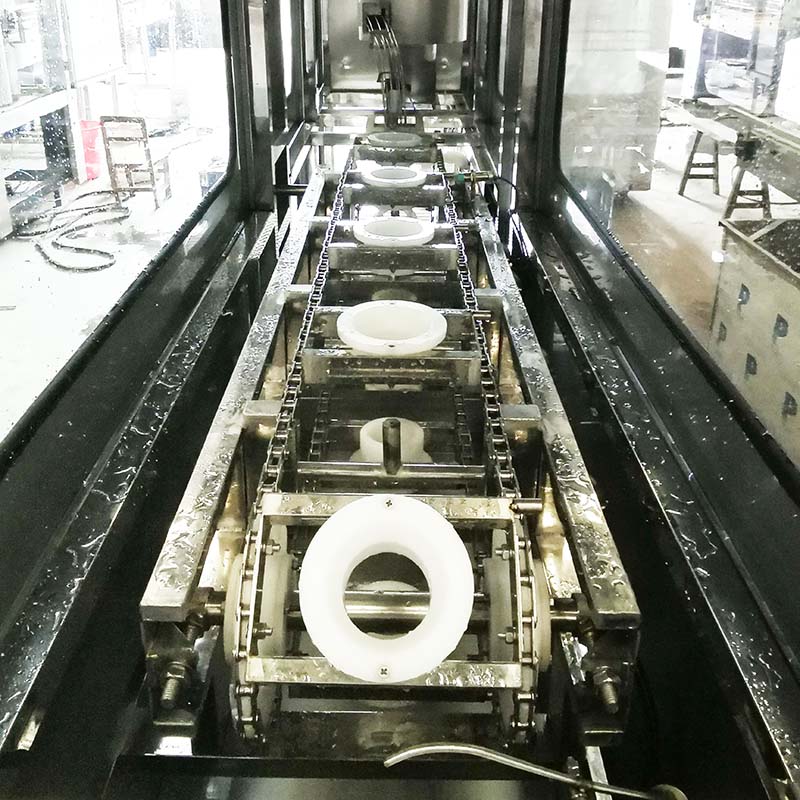

Single row, five working positions for washing, one filling head, one capping head |

||

First to Second working position: Inside washing with detergents, Third working station: drip out, fourth working position: Clean water washing, fifth working position: Pure water washing. |

|||

Outer size |

3170×700×1525(mm) |

||

Requirement of air compressor |

0.1 M³ 0.17 M³/Min 0.8Mpa/Cm² |

||

Requirement of water supply |

4M3/H |

||

Product Details

Water Filling Machine

When the bottle feeding optoelectronic switch in the end of machine detect bottle infeed, the conveyer chain in the washing machine will be run and drive the bottles to the first washing position, and bottle conveying unit stop and start rinsing process. The machine is with 8 rows and 16 washing positions for bottle elevating type rinsing, the maximum washing time is 18 seconds.

Washing pumps are using high standard CNP high-pressure pumps, and the pumps are set outside of the machine for easy maintenance. All the washing tanks are using round type best standard water tanks.

Working Positions

Water pump

Electrical control box

5 Gallon water filling machine