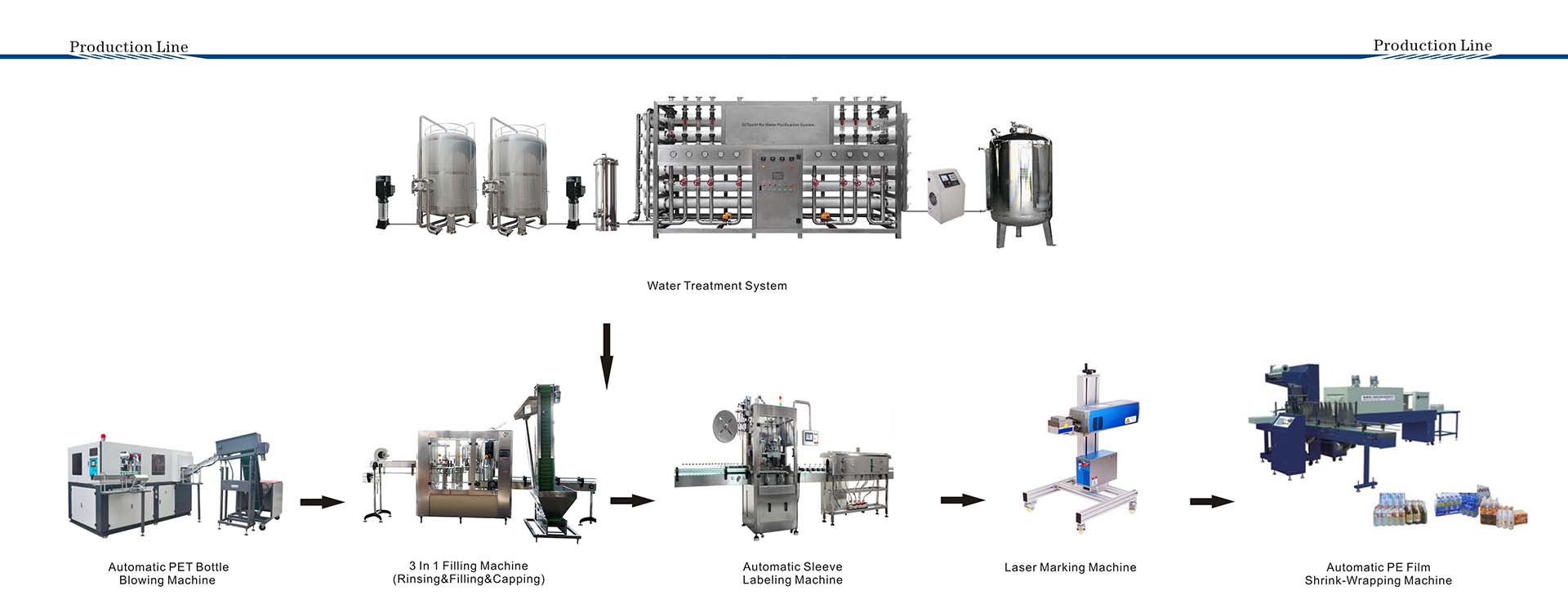

engineering service for mineral water plant

| Item | Name | Material | Model |

| 1 | Booster pump | SUS304 | CNP CDL8-30 |

| 2 | Mechanical filter | SS304/FRP | Φ750 x H1800 |

| 3 | Carbon filter | SS304/FRP | Φ750 x H1800 |

| 4 | Precise filter | Stainless steel | 30"×5 |

| 5 | UF membrane | hollow fiber | 4040 x 1m |

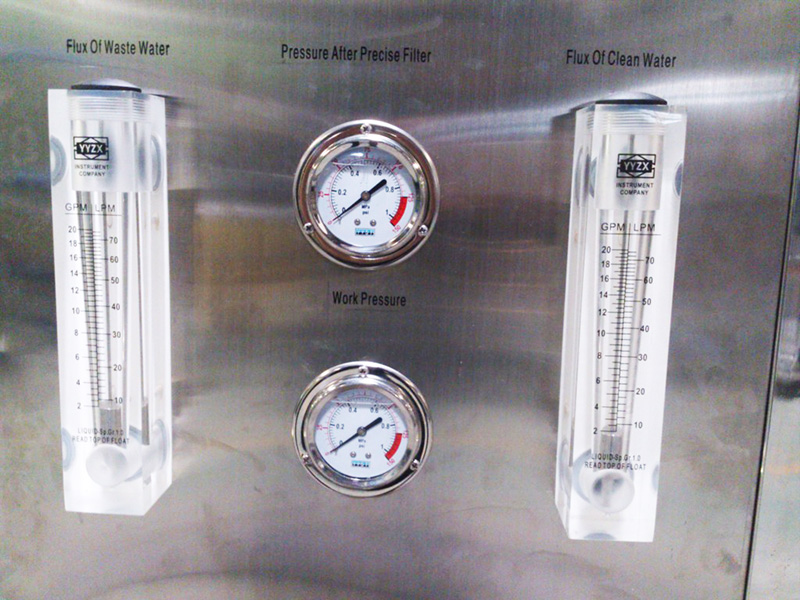

| 7 | Conductivity of the table | CM230A | |

| 8 | Panel flow meter | 35GMP | |

| 9 | Pressure gage | SUS304 | 1.5Mpa |

| 10 | Pressure Controller | P6E | |

| 11 | Main frame | SS304 | |

| 12 | Pipes and pipe fittings | PVC-U | DN40、DN32 |

| 13 | Control electric box | ||

| 14 | Screw/joint etc |

Product Details

Mineral water plant

UF processes are currently limited by the high cost incurred due to membrane fouling and replacement. Additional pre-treatment of feed water is required to prevent excessive damage to the membrane units.

- Design basis and treated water standard:

- Target water quality standard: Mineral water for Drinking

- Capacity of pure water production for UF system: 5,000 liters per hour

- Water utilization ratio : 50% - 65%

- Mode of Operation: Full Automatic

2. System requirements:

2.1 Inlet pipelines: inlet pipe connected with the raw water tank entrance.

2.2 Cable: According to the calculated capacity of electric power, the user should send it on the control cabinet.

2.3 Outlet water pipelines: From pure water tank to the pure water using point.

2.4 Concentrated Water Treatment: Discharge to the wastewater pool (user considered).

2.5 Water temperature:5-35˚C

High quality electric components:Shneider,Omron,Mitsubishi,SIMENS.

UF Water Purification Systems

UF system

5000L UF Water Purification Systems

Leonard Industrial specializes in designing, engineering, manufacturing and delivery of different types of water treatment systems and bottle water & beverage filling packing machineries for the food, beverage, dairy, chemical, and environmental protection industries. We are aiming to develop long-team relationships with our customers and suppliers, working closely on project development and achieve complete customer satisfaction by providing excellent quality & reliable machineries, zero defect delivery, first class services and competitive prices.