Equipment |

Item |

Unit |

Specification |

Blowing Main Machine |

Machine Dimension |

mm |

200*110*210mm |

Weight |

kg |

800 |

|

Max Bottle Size |

ml |

1500 |

|

Minimum Bottle Size |

ml |

50 |

|

Maximum Bottle Mouth Diameter |

mm |

40 |

|

Minimum Bottle Mouth Diameter |

mm |

18 |

|

Maximum Bottle Diameter |

mm |

125 |

|

Maximum Bottle Height |

mm |

420 |

|

Mould Cavity |

mold |

4 |

|

Maximum Capacity |

pcs/h |

2200 |

|

Mould Clamping Power |

T |

5.7(56KN) |

|

Mould Thickness |

mm |

200(max) |

|

Mold stroke |

mm |

210 |

|

Maximum Stretch Length |

mm |

420 |

|

Working Pressure |

Mpa |

0.8-1.0Mpa |

|

Blowing Air Pressure |

Mpa |

2.0-3.0Mpa |

|

Voltage/ Power Capacity |

V/KW |

220V(110V)/1KW |

|

Preform Heater |

Machine Dimension |

mm |

1870*630*1450mm |

Weight |

kg |

260 |

|

Voltage/ Power Capacity |

V/KW |

380V/14KW |

Product Details

Blow molding machine is especially used to produce 3 gallon and 5 gallon bottles and is widely used to produce any shape of plastic from PET with neck finishes from 15mm-200mm.

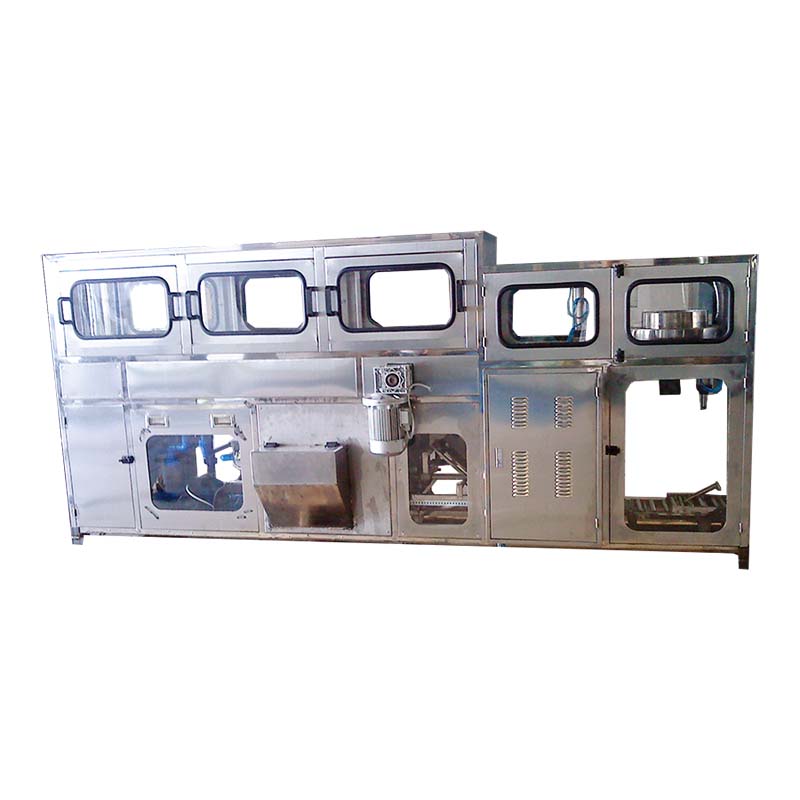

Semi-Automatic Bottle Blow Molding Machine(4 Cavity)

● Perfect function with economic investment.

● Small size and compact construction with no space waste.

● Easy to operate and maintain , operation by one person .

● Saving power and uneasy to worn out. Adopting new double crank four bars to lock mould, the cross fixed. Providing high pressure blowing system.

● We can provide performs and various bottle& cap molds for 5 gallon and 3gallon bottles to meet customer's requirements.

HY-B4 Semi-auto Bottle Blow Moulding Machine

4cavity Automatic Bottle Blow Moulding Machine

Precision air filter&High pressure air compressor

Plastic bottle

Workshop

Sipping

Leonard Industrial specializes in designing, engineering, manufacturing and delivery of different types of water treatment systems and bottle water & beverage filling packing machineries for the food, beverage, dairy, chemical, and environmental protection industries. We are aiming to develop long-team relationships with our customers and suppliers, working closely on project development and achieve complete customer satisfaction by providing excellent quality & reliable machineries, zero defect delivery, first class services and competitive prices.