| Capacity | 100 Bottles/hour |

| Bottle’s capacity | 18.9 Liters (equal to 5 gallons) |

| 11.3 Liters (equal to 3 gallons) | |

| Bottle’s specification (mm) | 5Gallon:Φ270×490×Φ56; 3Gallon:Φ230×420×Φ56 |

| Cap’s specification (mm) | Φ58×40 (strip:L18mm,W:7.5mm) |

| Rated input power | 2.3KW |

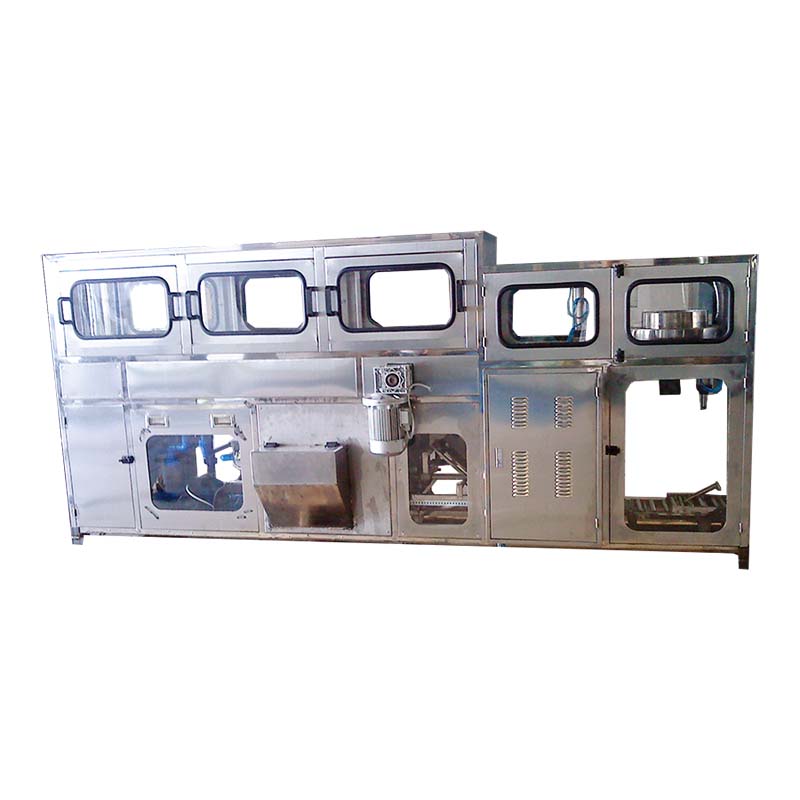

| Working Positions | 1) Single row, four working positions for washing, one filling head, one capping head. |

| 2) First and second working position: Inside washing with detergents, third working position: drip out, fourth working position: Pure water washing. | |

| Outer size | 3170×700×1525(mm) |

| Requirement of air compressor | 0.1 M³ 0.17 M³/Min 0.8Mpa/Cm² |

| Requirement of water supply | 3M3/H |

Product Details

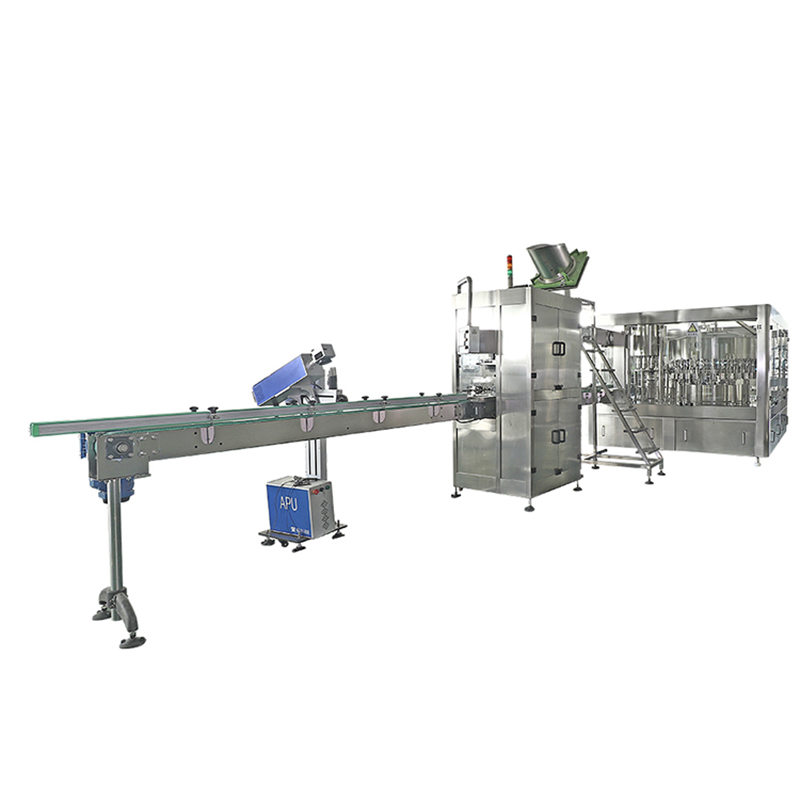

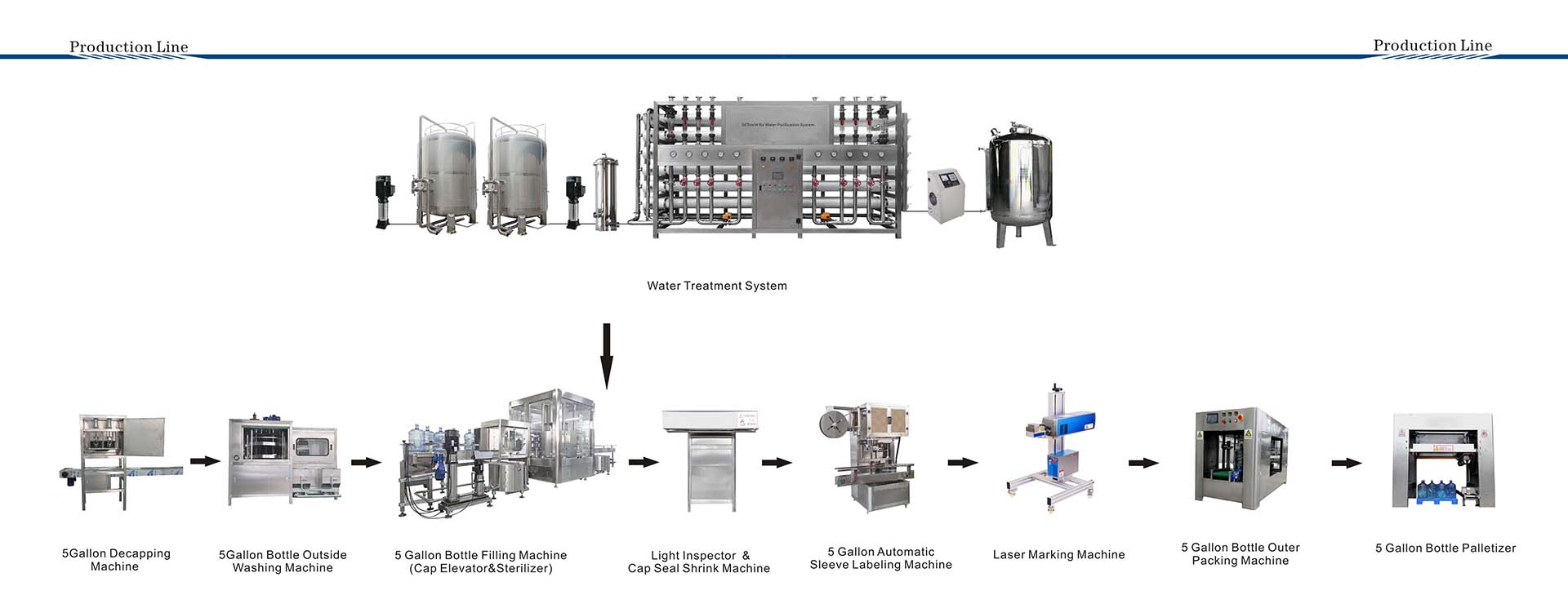

Water filling plant production line

Automatic Decapper---Bottle Exterior/Inner Washing Machine---Bottle-Feeding Machine---Bottle Rinsing Filling and Capping Machine--- Label-Shrinking Machine.

The device employs key components of electrical appliances and metal materials manufactured by named brand factories from home and abroad;

It is not only with the advanced technology, high automatization, easy operation and reliable performances, but also features with beautiful appearance, anti-corrodibility.

Cap press cover

Washing units

Finish bottle output

100BPH Water bottle filling machine

Leonard Industrial specializes in designing, engineering, manufacturing and delivery of different types of water treatment systems and bottle water & beverage filling packing machineries for the food, beverage, dairy, chemical, and environmental protection industries. We are aiming to develop long-team relationships with our customers and suppliers, working closely on project development and achieve complete customer satisfaction by providing excellent quality & reliable machineries, zero defect delivery, first class services and competitive prices.