| Specification | Unit | DFW1680 | |

| Injection Unit | Screw Diameter | mm | 45 |

| Screw L/D Ratio | L/D | 01:21.3 | |

| Injection Capacity In Theory | cm3 | 358 | |

| Injection Weight | g | 326 | |

| Injection Pressure | Mpa | 170 | |

| Screw Speed | rpm | 0-200 | |

| Clamping Unit | Clamping Force | KN | 1680 |

| Toggle Stroke | mm | 380 | |

| Space Between Tie-bars | mm | 455*455 | |

| Max.Mould Height | mm | 500 | |

| Min.Mould Height | mm | 180 | |

| Ejector Stroke | mm | 140 | |

| Ejector Tonnage | KN | 53 | |

| Ejector Number | Piece | 5 | |

| Others | Max. Pump Pressure | Mpa | 16 |

| Pump Motor Power | kw | 15 | |

| Heater Power | kw | 10.25 | |

Product Details

Injection machine is especially used to produce PET bottles&caps preform and is widely used to drinking water bottling production line

Injection Machine

Adopt the variable pump with highsensitivity,the flow and pressure are controlled by computer.and it can match with the actual consump-tion.the whole system has obvious energy saving effect,faster reponse,and smaller impact of action

Injection Machine

Hopper Dryer

Vacuum auto-loader

Water Chiller

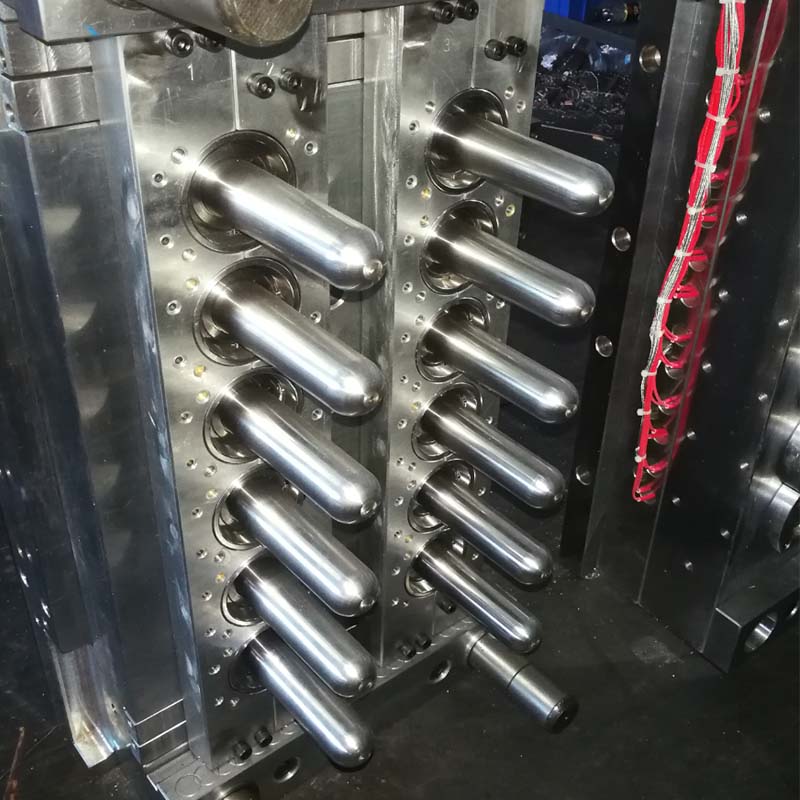

Preform Mold

Injection Machine Shipment

Workshop

Sipping

Leonard Industrial specializes in designing, engineering, manufacturing and delivery of different types of water treatment systems and bottle water & beverage filling packing machineries for the food, beverage, dairy, chemical, and environmental protection industries. We are aiming to develop long-team relationships with our customers and suppliers, working closely on project development and achieve complete customer satisfaction by providing excellent quality & reliable machineries, zero defect delivery, first class services and competitive prices.