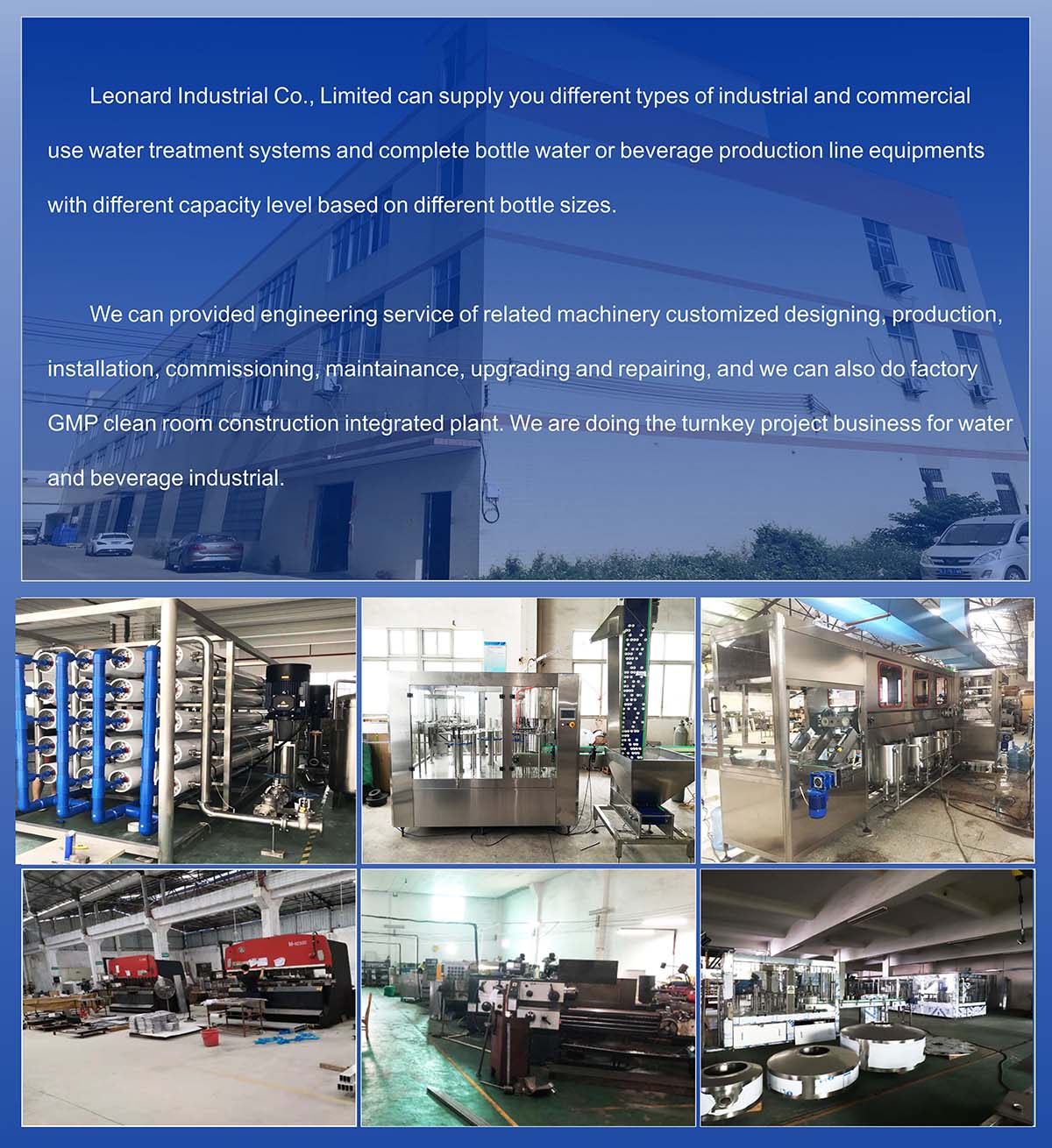

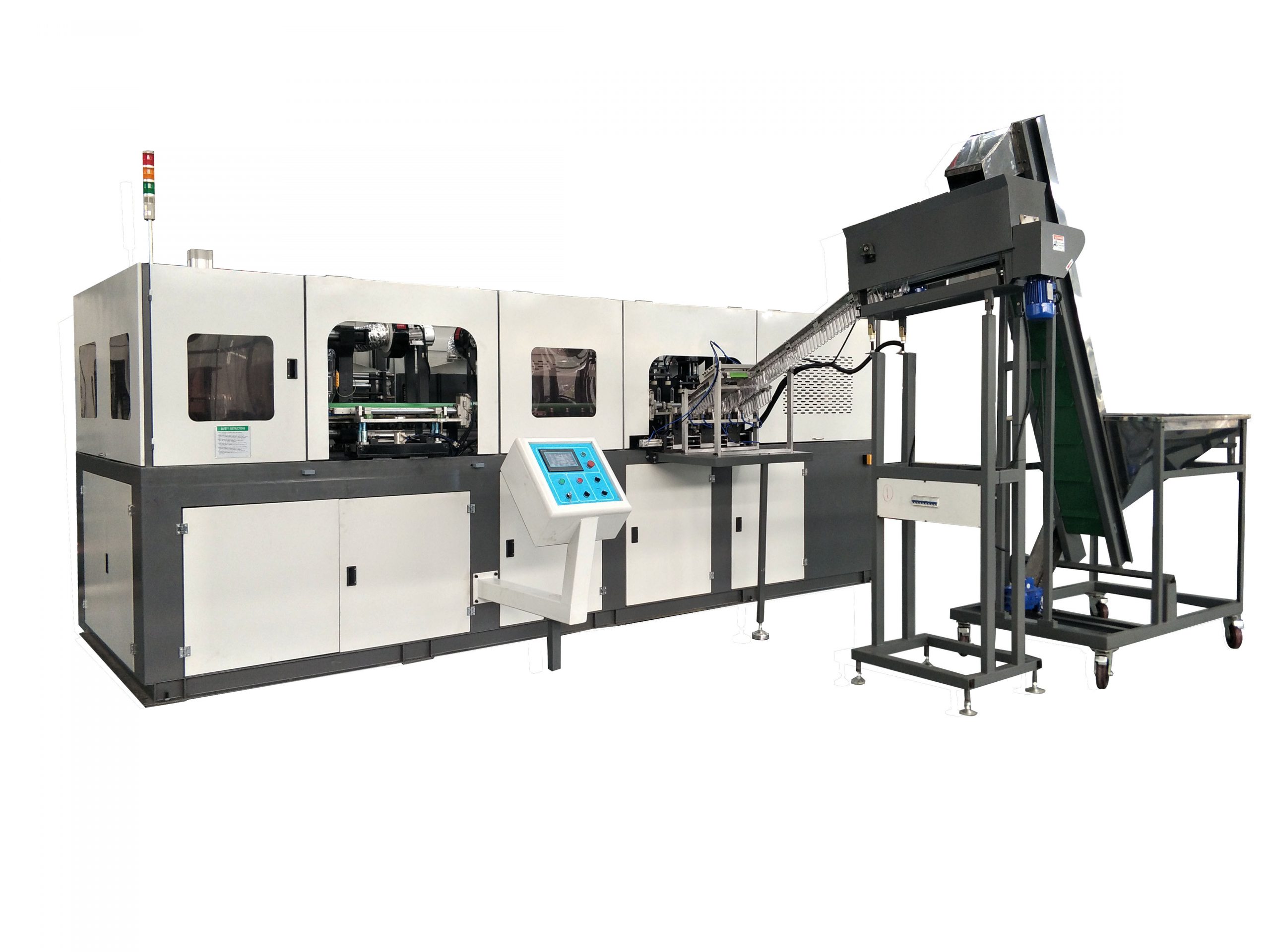

Automatic Bottle Blow Molding Machine

| Container | Max Volume | L | 2 |

| Max Neck Diameter | mm | 38 | |

| Max Container Diameter | mm | 105 | |

| Max Container Diameter | mm | 335 | |

| Cavity | 6 | ||

| Theoretical Output | bph | 6000 (500ml) | |

| Electrical | Total Power | KW | 47 |

| Heating Power | KW | 44 | |

| Max Heating Power | KW | 60 | |

| Air Compressor | Operating Pressure | Mpa | 0.7 |

| Low Pressure Consuming | L/min | 1400 | |

| Blowing Pressure | Mpa | 3.5 | |

| High Pressure Consuming | L/min | 3000-5000(**) | |

| Chiller | Pressure | Mpa | 0.3-0.5 |

| Temperature | ℃ | 10-12 | |

| Flow Rate | L/min | 30 | |

| Machine | Machine Size | m | 4.8x2.3x2.03 |

| Machine Weight | Kg | 4500 | |

| (**)Depending on bottle size, shape and weight. | |||

| (*)Depending on bottle size and operation conditions. | |||

Product Details

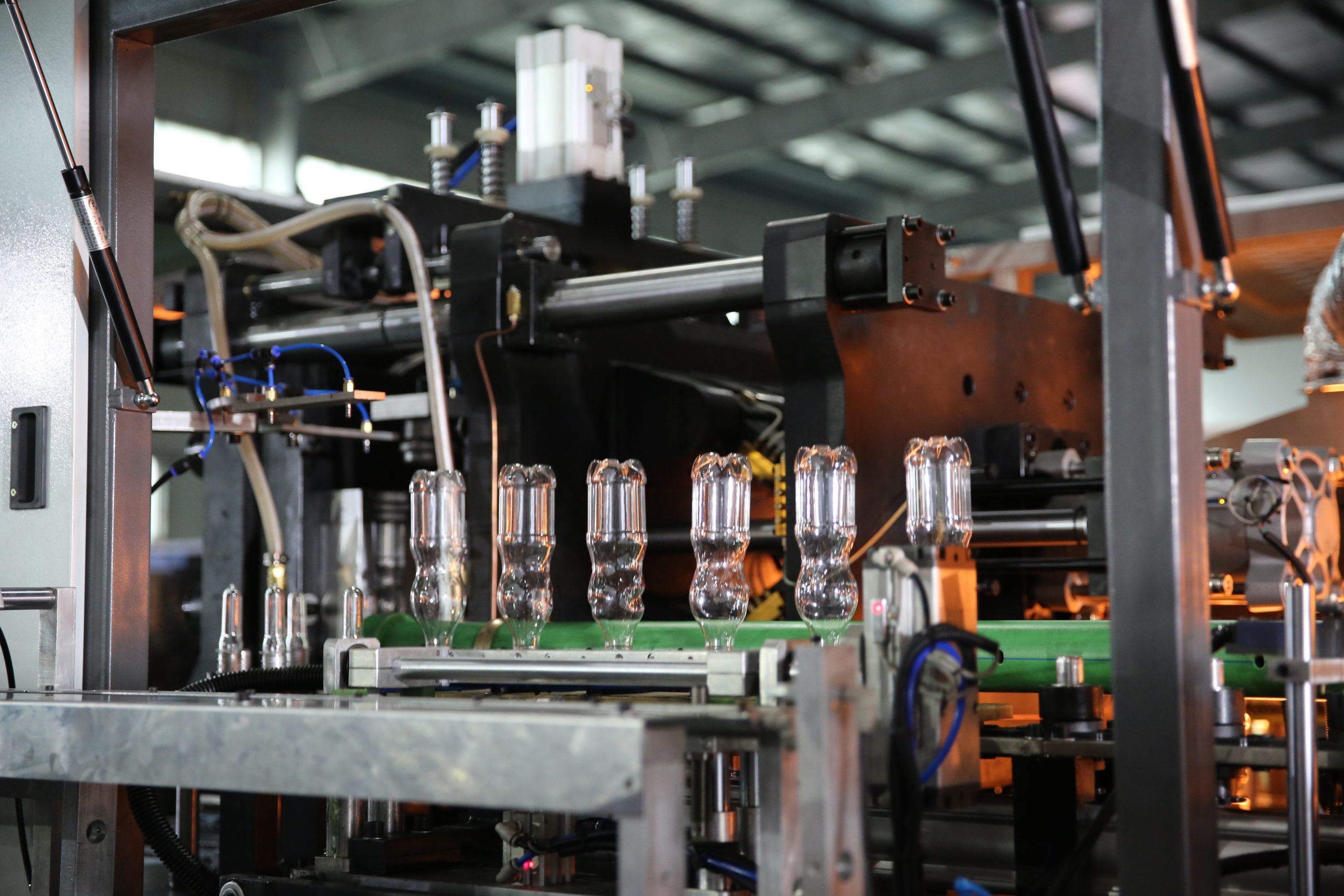

Blow molding machine is especially used to produce 3 gallon and 5 gallon bottles and is widely used to produce any shape of plastic from PET with neck finishes from 15mm-200mm.

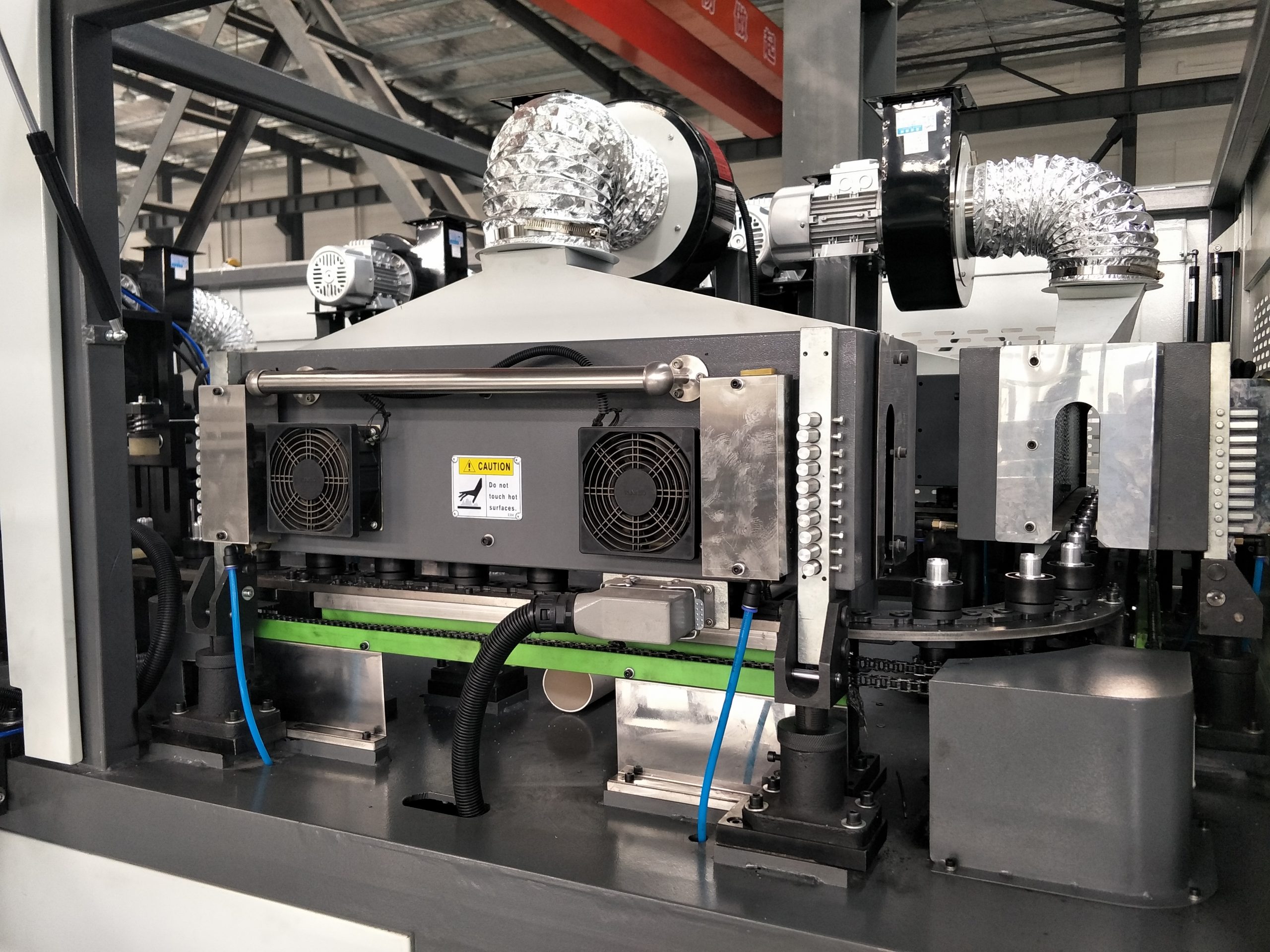

HY-6000 is the fastest liner blow molding machine in mainland of China by now. HY-6000 reaches around 6000BPH for 500ML bottle. Its baking tunnel is separated from the blow station so that time for mold opening is shortened with a result of speedy blowing and high output, damage to machine is lessened so as to keep reliable performance and prolong service life, as well as machine runs more smoothly and steadily.

HY-6000 is controlled by PLC. The whole process from preform feeding to bottle discharging is completed automatically with advantages of labor saving and no pollution. HY-6000 consists of three main parts: preform loading system, Heater channel & blow station.

Automatic Bottle Blow Molding Machine

Automatic Bottle Blow Moulding Machine

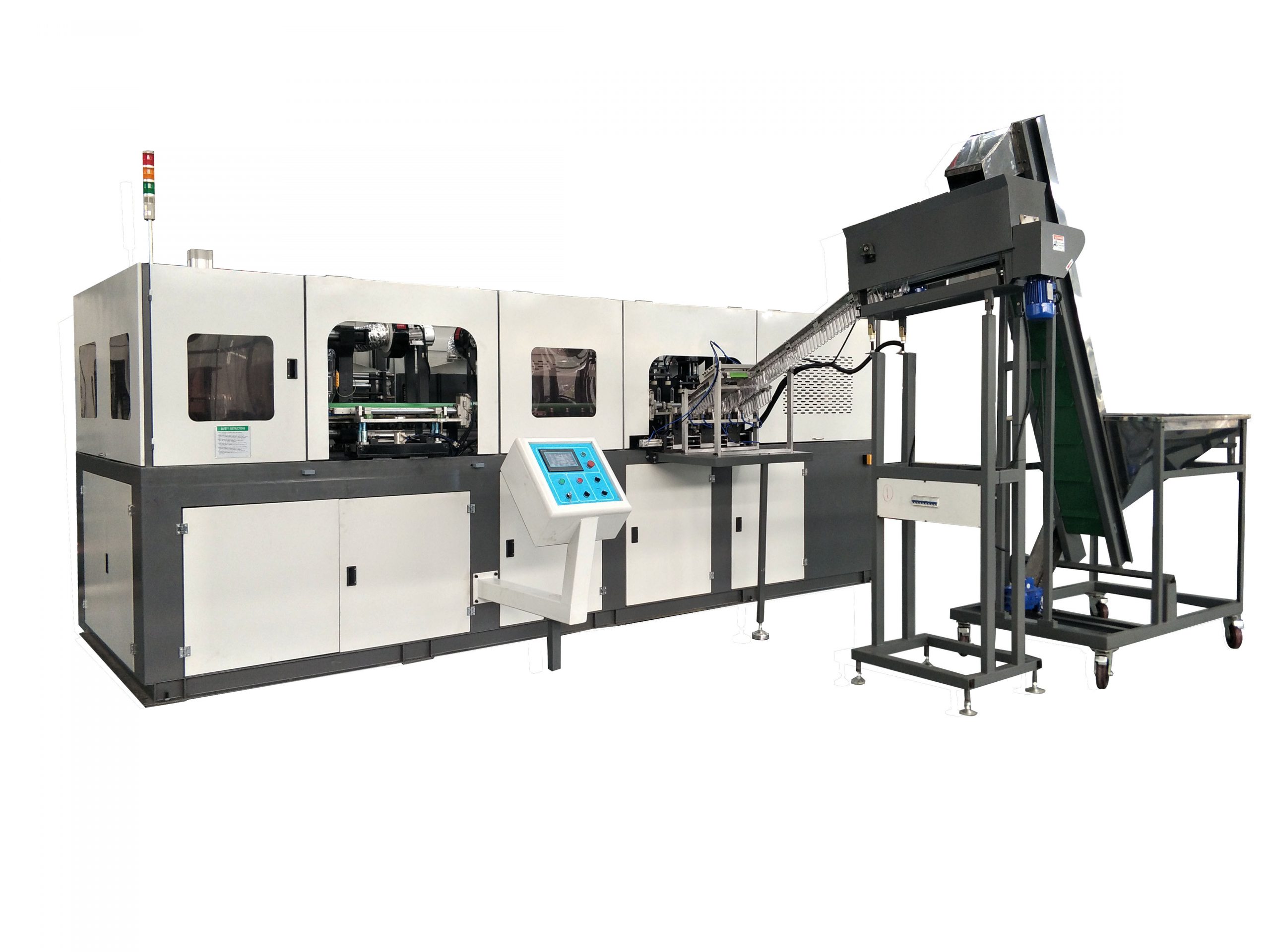

Blow Moulding Detailed

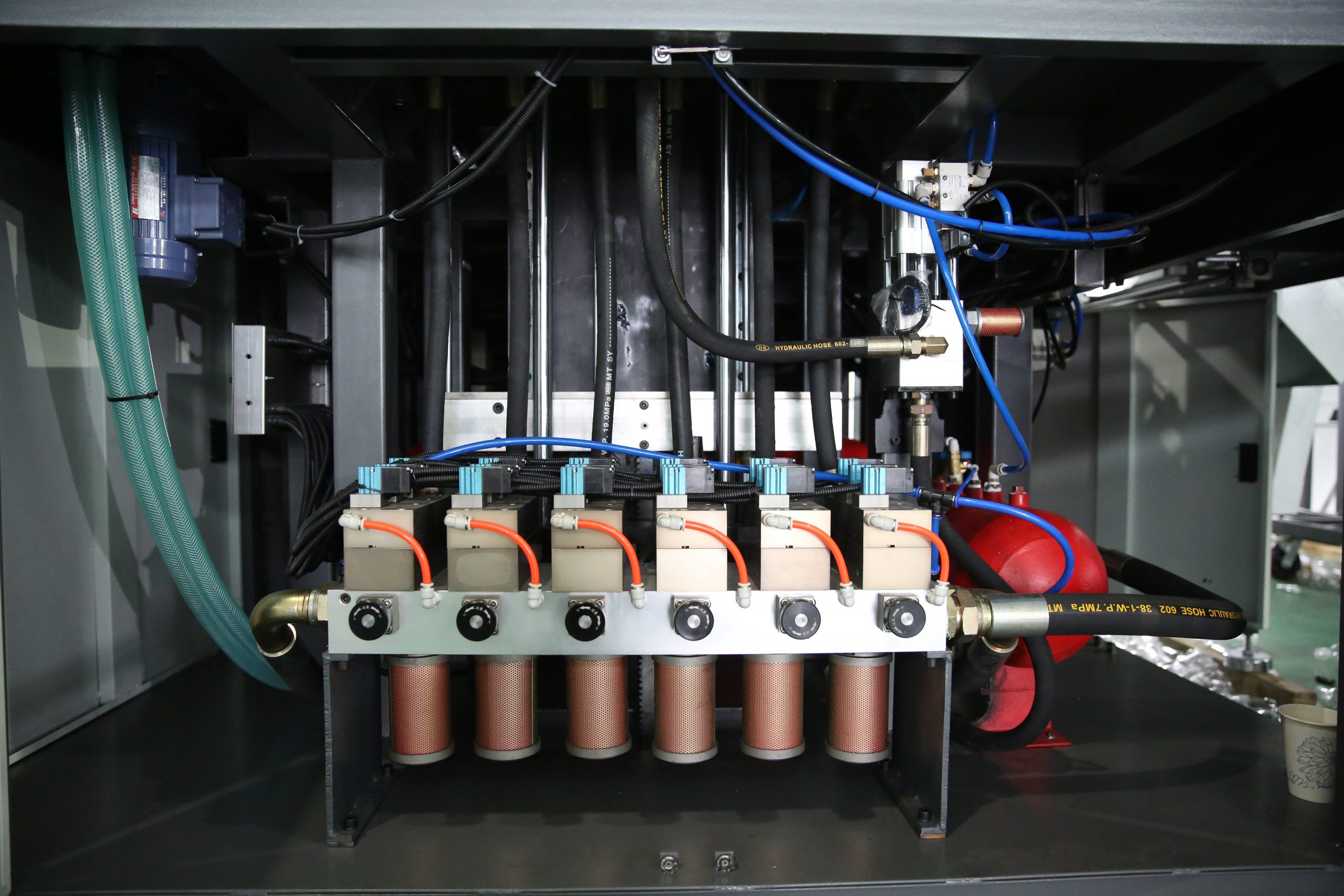

Moulding part

PET blowing moulding machine

Plastic bottle

Automatic Blow Molding Machine (Model: HY-6000)